- Learning and Development

A Guide to Manufacturing Training Videos

A powerful tool for training, the use of video has grown rapidly in recent years, becoming an increasingly important way for manufacturing companies to educate and train their employees in an interactive and engaging way. Video training is also instrumental to a company’s revenue, with The Educators reporting that 42% of companies using video for training are seeing an increase in income.

Additionally, the use of video allows for the creation of immersive, interactive learning experiences that can help workers better understand complex concepts and procedures.

As a critical component of modern manufacturing communication and training, there are a number of ways in which video can be used to enhance employee learning and development. From creating product demonstrations to offering virtual tours of manufacturing facilities, video is a versatile and engaging medium that can help companies build a more knowledgeable, skilled, and productive workforce.

8 Ways Modern Manufacturers Put Video to Work

Learn how to improve internal training, preserve the knowledge of retiring experts, and more.

In this guide, you will learn

- How Manufacturing Companies Can Use Video for Training

- What Are the Benefits of Using Video for Manufacturers?

- How is video being used to improve manufacturing operations?

- What are the obstacles for training manufacturing employees?

- How to Effectively Train Manufacturing Workers

- How to empower manufacturing employees

- Best practices for training manufacturing workers with video

- The Future of Manufacturing Training

How Manufacturing Companies Can Use Video for Training

Video allows companies to create engaging and interactive learning experiences, as well as standardize training procedures across different locations.

💡 Video-based training has been shown to increase retention rates by 25-60%, according to The Research Institute of America, compared to traditional training methods.

There are a number of ways in which manufacturing companies can use video for training. These include:

- Demonstrating proper use of equipment and machinery

- Presenting product knowledge and information

- Providing step-by-step instructions for processes and procedures

- Sharing best practices and safety tips

- Conducting virtual job shadowing or on-the-job training

- Offering continuous learning and skill development opportunities

- Providing onboarding and orientation for new hires.

What are the Benefits of Using Video for Manufacturers?

Manufacturers can greatly benefit from using video for training, communicating with, and onboarding their employees. These benefits include:

- Increasing operational efficiency

- Creating a positive company culture

- Increasing employee satisfaction, retention, and empowerment

- Boosting a company’s status as an ideal employer

- Standardization of training across locations and departments

- Flexibility for employees to access training materials at their own pace

- Enhanced collaboration and communication among employees

- Reduction of training costs compared to traditional in-person training

- Improved overall quality and efficiency of training programs

Additionally, videos can be easily accessed and viewed on-demand, which makes it convenient for employees to refer back to them when they need to refresh their knowledge. By using videos for training, manufacturing companies can improve the efficiency and effectiveness of their training programs, resulting in a better-informed and more skilled workforce.

💡 69% of people say that companies could improve their onboarding process by using video.

How is video being used to improve manufacturing operations?

Video training provides a unique opportunity for employees to see, hear, and understand complex manufacturing processes in a way that is easy to comprehend. The visual and auditory components of video training can help to reinforce learning and encourage retention of information.

Here are some ways in which video is being used to improve manufacturing operations:

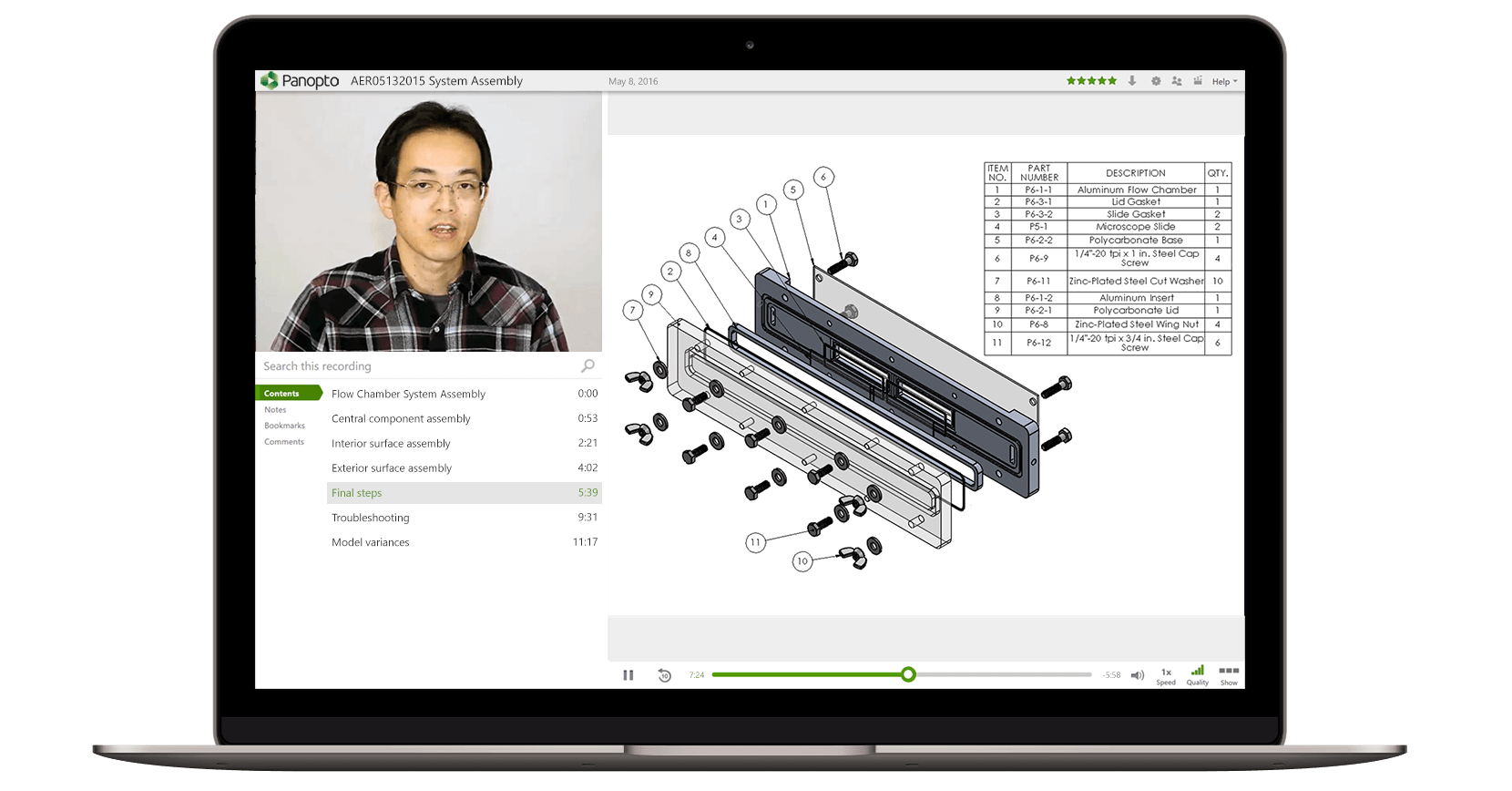

1. Enhanced Visual Demonstrations for Complex Procedures

Video training provides a visual demonstration of processes, procedures, and techniques that is easily understood by employees. This eliminates the possibility of misunderstandings or misinterpretations of written instructions. Visuals also help people retain information better and provide a reference point for employees to check if needed.

2. Reducing Downtime with Video Training

One of the biggest benefits of video training in manufacturing operations is the reduction of downtime. When employees are trained on a new process or procedure using video, they are able to see a visual representation of the steps involved, which minimizes the chance of making mistakes. This is especially important in industries where production is time-sensitive and costly, as every minute of downtime can have significant financial consequences.

3. Standardizing Safety, Compliance, and Skills Training Procedures

In a manufacturing setting, it’s crucial to have consistent processes and procedures in place. Video training allows for standardization of safety, compliance, and skills training procedures, ensuring that all employees receive the same information and are taught the same methods. This helps to avoid discrepancies in skills taught and ensures consistency across the production line.

4. Keeping Up with Technological Advancements

The manufacturing industry is constantly evolving, with new technologies and techniques being developed all the time. Video training provides an efficient and cost-effective way for employees to learn about these advancements, ensuring that the manufacturing operation stays up-to-date and remains competitive in the marketplace.

What are the obstacles for training manufacturing workers?

There can often be obstacles involved in training manufacturing employees. These include:

1. Lack of Time and Resources

One of the biggest obstacles for training manufacturing workers is the lack of time and resources. Manufacturing is a fast-paced, high-pressure environment where every minute counts. Taking workers off the production line for training can result in decreased productivity and increased costs. Additionally, many companies do not have the budget or resources to invest in training programs and materials.

2. Resistance to Change

Another challenge is resistance to change. Some workers may resist new training programs and technologies because they are comfortable with the way things have always been done. This resistance can be due to fear of the unknown, lack of trust in new systems, or simply not seeing the value in change.

3. Technological Changes

The manufacturing industry is constantly evolving, with new technologies and processes being introduced regularly. Keeping workers trained and up-to-date with these changes can be difficult and time-consuming. Additionally, many workers may not have the technical skills or background to easily adapt to new technologies.

4. High Turnover Rates

High turnover rates can make it difficult to provide ongoing training to workers. When workers are constantly coming and going, it can be challenging to provide consistent training and ensure that all workers are up-to-date on the latest processes and technologies.

5. Limited Availability of Skilled Instructors

Another obstacle is the limited availability of skilled instructors. Finding trainers with the expertise and experience to effectively teach new technologies and processes can be a challenge. Additionally, many companies may not have the budget to hire additional trainers or bring in outside experts.

So, what can you do about these obstacles? By focusing on empowering your staff, you can transform your organizational learning into consistent, engaging training that meets the needs of your employees.

How to Effectively Train Manufacturing Workers

Effectively training manufacturing employees is essential for ensuring the success and competitiveness of a company. Proper training helps workers develop the skills and knowledge they need to perform their jobs efficiently and effectively, resulting in increased productivity and reduced errors.

Well-trained workers are also more likely to be engaged and motivated, leading to lower turnover rates and improved morale. In addition, training helps employees stay up-to-date with the latest processes and technologies, allowing the company to stay ahead of the competition and respond to changes in the market. Effective training also helps to build a culture of continuous improvement, where workers are encouraged to develop their skills and take on new challenges.

📣 “With Panopto, [employees] have the option to prepare for a course in advance and thereby learn faster. Moreover, the ones who were not able to participate physically still have the opportunity to benefit from the courses.”

Birgitte Wilki, Administrative Coordinator at Group Technology at ROCKWOOL Group Operations & Technology Unit

How to empower manufacturing employees

Empowering manufacturing workers is vital not only for morale and retention, it also increases workers’ ability to do their job successfully.

💡 Manufacturing frontline employees saw a 112% increase in engagement when empowered with improving processes, while there was a 74% increase in engagement resulting from frequent employee recognition and mastering new skills.

Here are three ways to empower your manufacturing workers:

1. Communication

Encouraging open communication between management and employees can help build trust and a sense of ownership among workers.

2. Training and Professional Development

Providing ongoing training and professional development opportunities can increase workers’ skills and confidence, leading to improved performance and job satisfaction.

3. Recognition and Rewards

Recognizing and rewarding employees for their contributions can boost motivation and create a positive workplace culture. By making employees feel valued, they will be more motivated to perform their best and contribute to the success of the organization.

Best practices for training manufacturing workers with video

As we’ve just explored, empowering your workers is vital, and one tool that can help employees successfully receive recognition, professional development, and open communication is video. These best practices can guide you to develop consistent, effective training using video that strengthens engagement and increases productivity.

1. Create relevant and consistent training with on-demand content

Video training allows you to create consistent content that is relevant and specific to the tasks and responsibilities of workers. By providing a standardized and repeatable method of learning and delivering information to all employees, video helps ensure that everyone receives the same message and understanding.

2. Incorporate interactive elements to strengthen engagement

Encourage interactivity by including elements such as video quizzes, simulations, and gamification. This helps workers retain information and apply it on the job. Utilizing a video learning library can also enable users to personalize their viewing experience and increase interactivity.

3. Provide an accessible learning experience for all employees

Make training videos accessible to all workers, regardless of their location or work schedule, by using a cloud-based platform such as Panopto. On-demand learning enables employees to easily digest training anytime, anywhere, whether in an office or on-site. In addition, video offers a greater level of accessibility to workers who can utilize tools like captions or watching videos at a slower or faster speed.

4. Evaluate engagement and track progress

Did you know that 70% of organizations do not track quantitative training feedback and 89% rarely measure training ROI against learning outcomes desired by leadership? Evaluate the effectiveness of video training through data and analytics that help companies understand how employees are interacting with content. This information can be used to make continuous improvements to the training program.

By incorporating these key practices, organizations can provide effective and engaging training that helps manufacturing workers improve their skills and contribute to the success of the organization.

The Future of Manufacturing Training

As technology advances and the need for effective and efficient training increases, manufacturing will continue to embrace video as a flexible and interactive way to deliver training to workers, regardless of their location or work schedule.

The advancement of artificial intelligence and machine learning is expected to play a significant role in the future of manufacturing training. Video training platforms that utilize elements of AI can personalize training for each worker, tailoring the content to their individual learning styles and pace. This can lead to more effective training and improved skills acquisition, ultimately leading to increased productivity and job satisfaction – and Panopto provides the tool to support these endeavors.

Schedule a Panopto demo

Our team will contact you promptly to answer questions and schedule you for a demonstration and a free trial of our video platform.