Train the Floor. Protect Throughput. Scale Knowledge with Video.

It usually starts with a walkthrough. A senior operator shows a new hire how to set up a line. A supervisor explains a safety step before a shift change. An engineer answers the same troubleshooting question… again.

That knowledge is critical. But it lives in people’s heads, on paper SOPs, or in conversations that disappear as soon as the shift ends. In manufacturing, that’s risky.

Because when training is inconsistent, the impact shows up fast:

- Slower ramp times

- Repeat errors

- Scrap and rework

- Downtime

- Safety incidents

- Missed production targets

Training on the floor isn’t an HR initiative, it’s an operational control lever. And video is one of the most effective ways to pull it.

Struggling to keep training consistent across shifts and sites?

See how manufacturers use video to standardize execution, reduce downtime, and protect safety without slowing production.

Why Video Works on the Shop Floor

Manufacturing work is visual, physical and sequential. People learn by watching the task, hearing the explanation, and seeing how it’s actually done. Video mirrors how operators naturally learn.

It allows workers to:

- Rewatch a setup before starting a job

- Pause and replay a safety step

- Review a process change mid-shift

- Get answers without waiting for a supervisor

Unlike documents or slide decks, video captures context. The motion, the timing, the small details that matter when equipment is running, and mistakes are expensive. That’s why video training sticks and why operators actually use it.

The Real Challenge Isn’t Creating Video. It’s Scaling It.

Most manufacturers already use video in some form. A phone recording here. A screen capture there. Maybe a shared folder full of files. But that approach breaks down fast.

- Training varies by shift and site

- Old versions stay in circulation

- SMEs get pulled off the line to retrain

- Safety teams can’t prove who watched what

- Operators waste time searching or guessing

As video grows, so does chaos. What manufacturers need isn’t more video. They need a system for video.

Panopto: The Operational Video Backbone for Manufacturing

Panopto is built for environments where training consistency, safety, and uptime matter.

It gives manufacturers a governed video layer that captures expert knowledge once and makes it available everywhere operators work. With Panopto, manufacturers can:

- Standardize training across shifts and plants: One approved way to do the job, available on demand.

- Reduce SME dependency: Experts record once instead of repeating the same explanations daily.

- Protect safety and compliance: Only the latest approved procedures are visible, with audit-ready proof of access.

- Reduce downtime: Operators search for the exact setup or fix instead of waiting or guessing.

- Accelerate onboarding and cross-training: New hires and redeployed operators get productive faster.

This isn’t about content storage. It’s about operational readiness.

Looking for a better way to scale training without adding risk or complexity?

Get a closer look at how Panopto supports safety, quality, and operations teams with version controlled, searchable training video.

What This Looks Like on the Floor

A process engineer records the correct setup for a critical machine. A safety lead updates a lockout procedure after a change. A maintenance tech captures a fix for a recurring issue.

Those videos are uploaded once and from there:

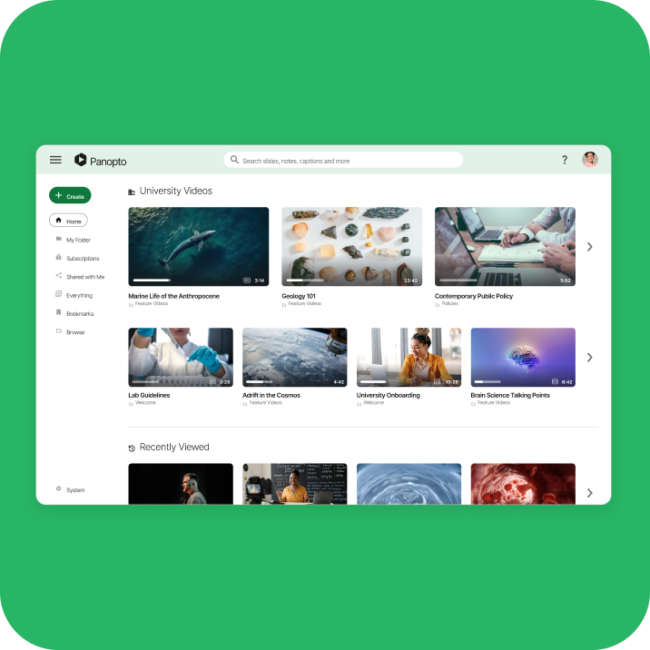

- Operators search by machine, task, or keyword

- Supervisors confirm readiness before a shift

- Old versions are automatically retired

- Training activity is logged and reportable

Instead of tribal knowledge, you get institutional knowledge. Instead of variance, you get consistency.

Training at the Point of Work

Panopto is designed to meet operators where they are.

On tablets.

On kiosks.

On shared workstations.

On mobile devices in maintenance areas or break rooms.

When something goes wrong, operators don’t need to leave the floor or track someone down. They search, watch, and act.

That matters when every minute of downtime costs real money.

Built for Safety, Quality, and Audits

In manufacturing, the risk isn’t missing training. It’s using the wrong training.

Panopto ensures:

- Clear version control for SOPs and safety content

- Controlled access by role and location

- Proof of who had access to which version and when

When incidents happen or auditors ask questions, the answers are already there. That confidence changes how teams operate.

Not Another Tool. A Layer That Connects What You Already Use

Panopto fits into the manufacturing tech stack without adding sprawl.

It complements:

- LMS platforms used for assignments and certifications

- Written SOP systems

- MES and line-level execution tools

- Existing identity and security systems

Instead of video scattered across drives, email, and personal tools, Panopto provides one governed place for operational video.

That’s why IT, Ops, Safety, and Quality teams can all get behind it.

From One Plant to Every Plant

The real power of video shows up at scale.

A best practice captured in one facility becomes the standard everywhere.

A process change rolls out across sites without delays.

A retiring expert’s knowledge stays in the organization.

Training stops being reactive. It becomes repeatable, measurable, and resilient.

See How Manufacturers Use Video to Protect Performance

Panopto helps manufacturers reduce preventable downtime, improve consistency across shifts and sites, shorten time-to-competency and strengthen safety and audit readiness.

If training touches safety, quality, or throughput in your operation, this is worth seeing.

Ready to see how it works in your manufacturing environment?

Get a tailored walkthrough focused on operator training, safety compliance, and operational consistency.

Training That Keeps the Line Moving

Manufacturing doesn’t slow down for training. Your training strategy shouldn’t slow production down either.

When operators can learn on demand, when knowledge is easy to find, and when processes are taught the same way every time, the entire operation runs better.

That’s what happens when video stops being ad hoc and starts being intentional.

Capture expertise once. Scale it everywhere. Protect what matters most.

See Panopto in action for manufacturing teams.

Latest News

-

- Webinar Recap

Understanding Student Video Behavior: Webinar Best Practices

Student video behavior reveals a clear pattern: learners navigate content strategically, searching for specific moments rather than watching linearly. A recent webinar featuring Shaun Searle from the University of Portsmouth and Ian Paice, Panopto’s Chief Customer Officer, explored how modern video platforms turn this behavior into better learning outcomes. Understanding How Students Use Video Analytics…

Understanding Student Video Behavior: Webinar Best Practices

-

- Webinar Recap

AI Learning with Video: Moving from Content Overload to Just-in-Time Training

In a recent webinar hosted in partnership with Training Magazine, Amy Clark, Chief Operating Officer of Panopto, and Susy Martins, founder and CEO of Advise2Rise, explored how AI-powered learning is transforming corporate training. The Disruption Ahead The workplace faces unprecedented transformation. “By 2030, it’s projected that 70% of the skills used in most jobs today…

AI Learning with Video: Moving from Content Overload to Just-in-Time Training

-

- Remote Work

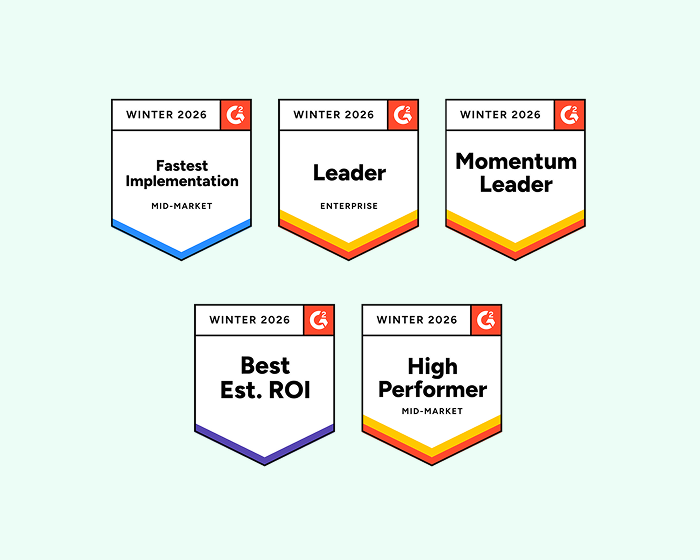

Panopto Customers Drive G2 Winter 2026 Recognition for Video-Powered Learning

Powered by real customer feedback, Panopto was recognized with multiple G2 Winter 2026 badges across video and learning categories—reinforcing the impact of intuitive, scalable video-powered learning.

Panopto Customers Drive G2 Winter 2026 Recognition for Video-Powered Learning