Video Software for Manufacturing Operations

Your manufacturing expertise shouldn’t disappear when experienced workers retire or equipment changes. Panopto captures critical knowledge on video so every employee can learn the right procedures, safety protocols, and technical skills exactly when they need them.

An industry-leading video content management platform

How can video software transform your manufacturing company?

See Manufacturing Video Software Demo in 2 Minutes

Watch How Factories Use Video for Safety Training and Process Documentation

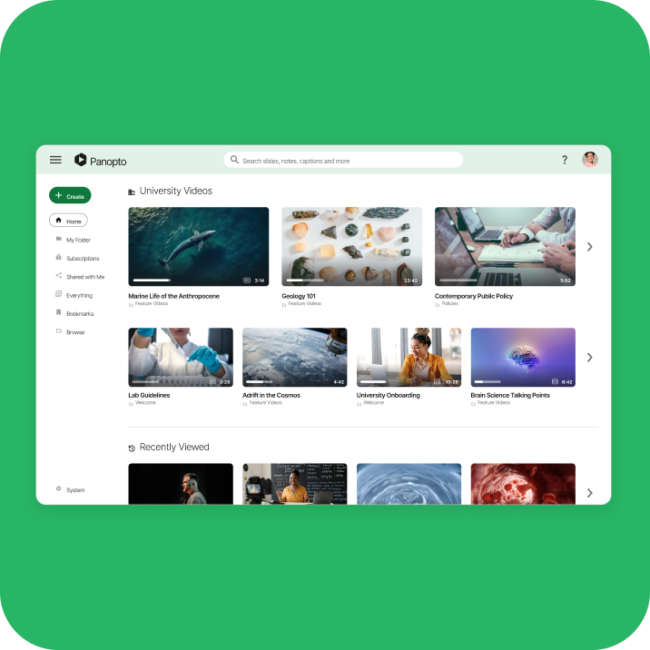

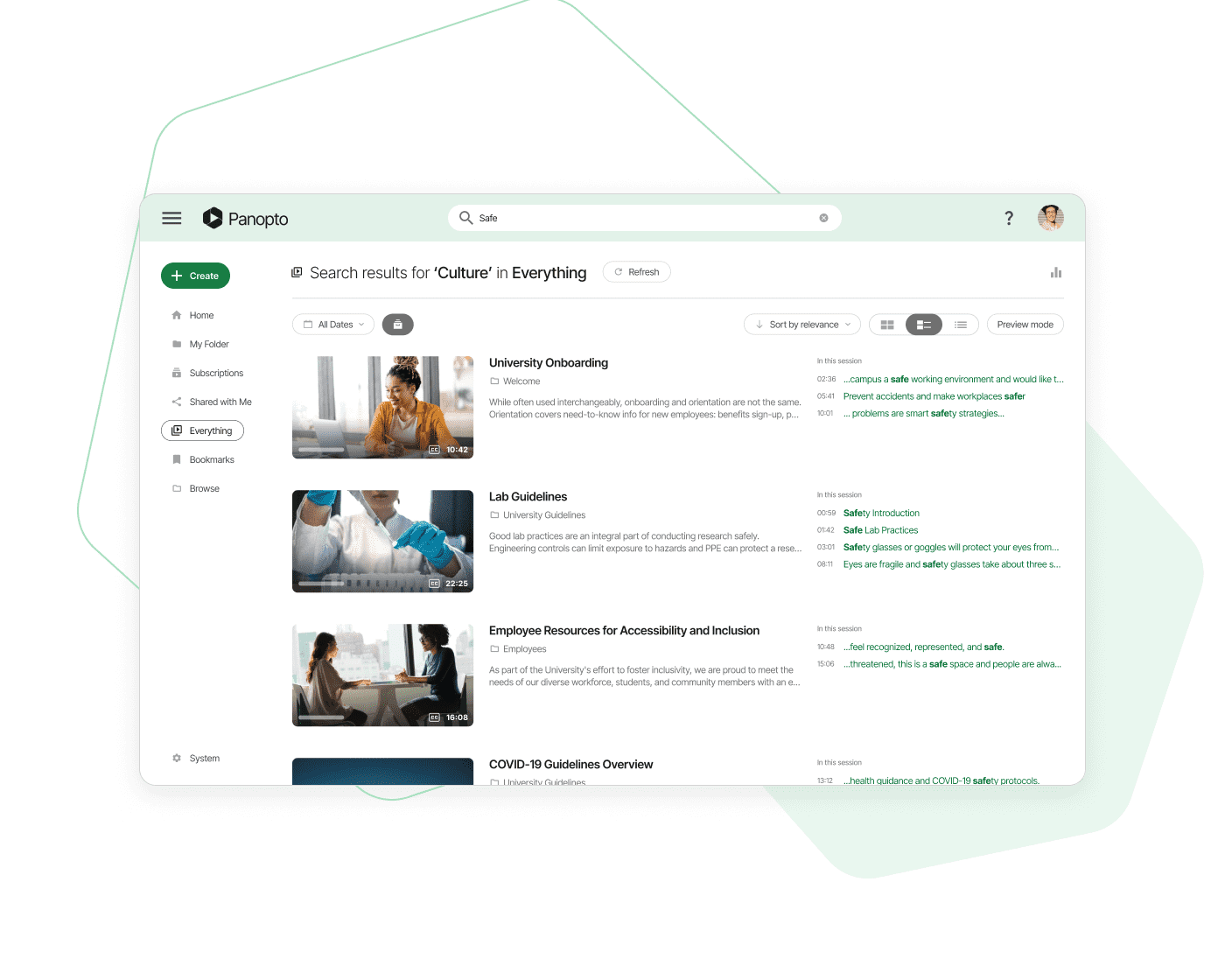

Share manufacturing training and technical knowledge on-demand for frontline flexibility

Access Equipment Manuals, Safety Procedures, and Process Videos Anywhere on the Shop Floor

Your frontline workers don’t have time to hunt through file servers or track down supervisors when they need information. They need answers now while the machine is in front of them.

Panopto’s video platform puts training at their fingertips. Search the entire video library from any device or tablet on the shop floor. Find the specific procedure they need, watch it as many times as necessary, and get back to work. The entire library is indexed automatically, so searching works even when they don’t remember the exact title.

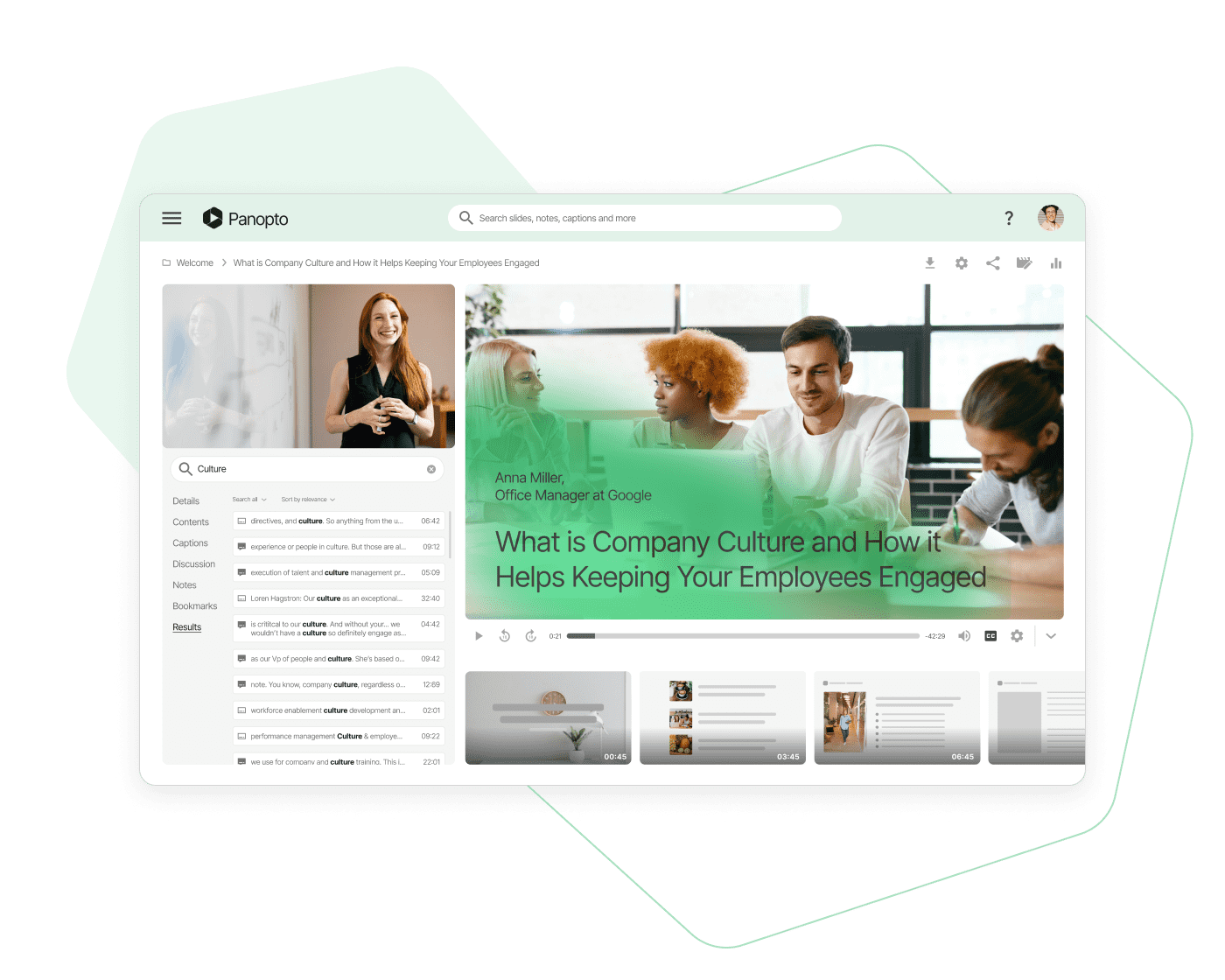

Maintain critical manufacturing expertise and corporate knowledge assets

Preserve Knowledge Through Video Documentation and Training Libraries

Knowledge gaps threaten production. Experienced employees retire and take decades of troubleshooting expertise with them. Shift changes mean the person who knows how to fix a recurring issue isn’t available when it happens again. Organizational changes scatter institutional knowledge across different locations.

Panopto helps you capture and preserve that expertise before it disappears. Recording is simple enough that anyone can do it without video production skills. Create training content, share it across locations, and build a knowledge library that survives employee turnover.

Break down language barriers for effective manufacturing learning

Automated Translations and Multi-Language Captions for Global Manufacturing Teams

Your workforce speaks different languages. Safety training and equipment procedures need to reach everyone regardless of their primary language.

Panopto automatically captions videos in over 20 languages. Spanish-speaking employees get captions in Spanish. Polish-speaking workers get Polish captions. Everyone learns the same safety procedures and quality standards in a language they understand. This keeps training consistent across your global operations while meeting diverse language needs.

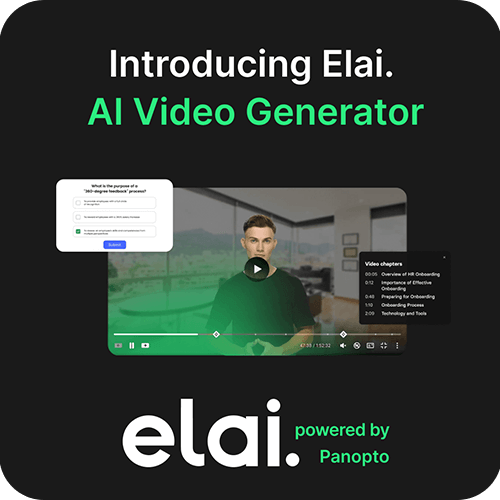

Make manufacturing onboarding and upskilling easier and more effective

Create Interactive Training Modules for Equipment Operation and Safety Protocols

New equipment requires retraining. Employee turnover means constant onboarding. Skills gaps need upskilling programs. You can’t pull trainers off the floor every time someone needs instruction.

Build an on-demand training library with videos covering equipment operation, safety procedures, and best practices. Add quizzes to verify understanding and track who completed what training. Analytics show you engagement levels and compliance status so you know exactly where your workforce stands on certifications and required training.

Find our latest blog posts

Frequently Asked Questions:

Can shop floor workers access training videos on mobile devices?

Yes. Employees can watch training videos on tablets, phones, or any device with a browser. Download videos for offline viewing in areas with poor connectivity, then sync progress when they reconnect to the network.

How do we capture knowledge from experienced workers who aren’t comfortable with technology?

Recording is as simple as clicking a button. Veterans can record themselves performing procedures using a phone, tablet, or laptop. No editing or technical skills required. If they can make a video call, they can create training content.

Can we track which employees watched required safety training?

Yes. Panopto tracks who watched which videos, how long they watched, and whether they passed embedded quizzes. Export reports for compliance documentation or audits. You’ll have proof of training completion before inspectors ask for it.

What happens to our training library if we switch manufacturing systems?

Your video library is independent of your manufacturing systems. Training content stays accessible regardless of equipment changes or system updates. Videos created five years ago remain searchable and usable today.